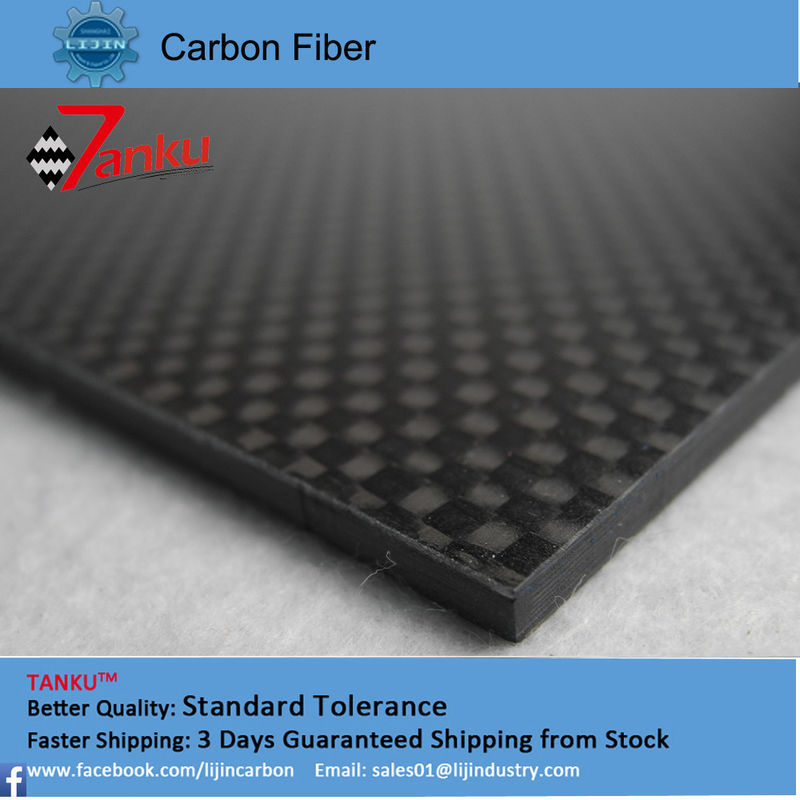

High Strength Reinforced Plastic 3K Carbon Fiber Plate , Matte Plain Carbon Fiber Sheets

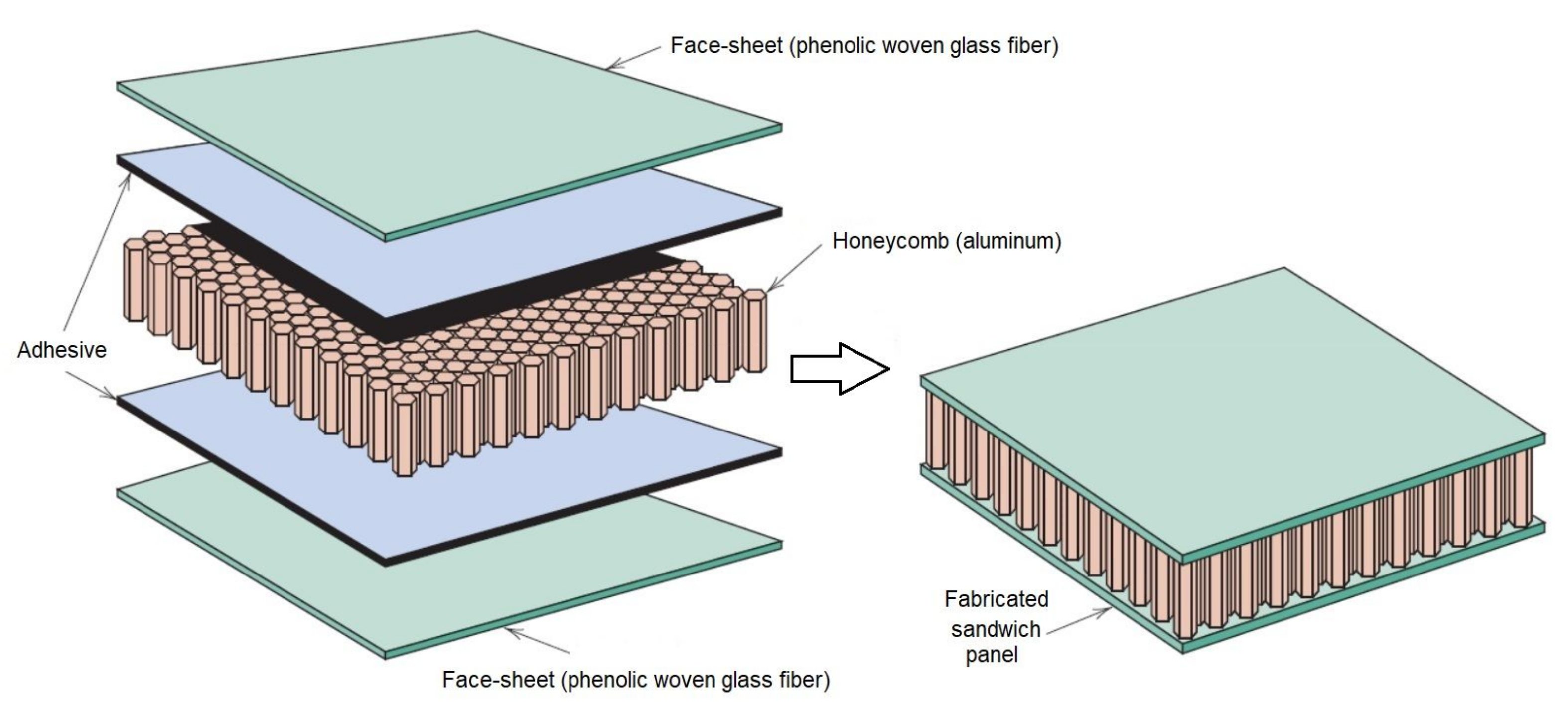

Fiber-Reinforced Polymer (FRP) materials are composite materials that typically consist of strong fibers embedded in a resin matrix. The fibers provide strength and stiffness to the composite and generally carry most of the applied loads. The matrix acts to bond and protect the fibers and to provide for transfer of stress from fiber to fiber through shear stresses.

Carbon Fiber Reinforced Plastics (CFRP) Trends

Fiberglass reinforced plastic (FRP) is a material used in the manufacture of lightweight construction products such as: Roofing materials. Cabinet sets. Fencing. Pipes. The manufacturing process begins with cutting and molding the desired shape before pouring resin into the clay mold.

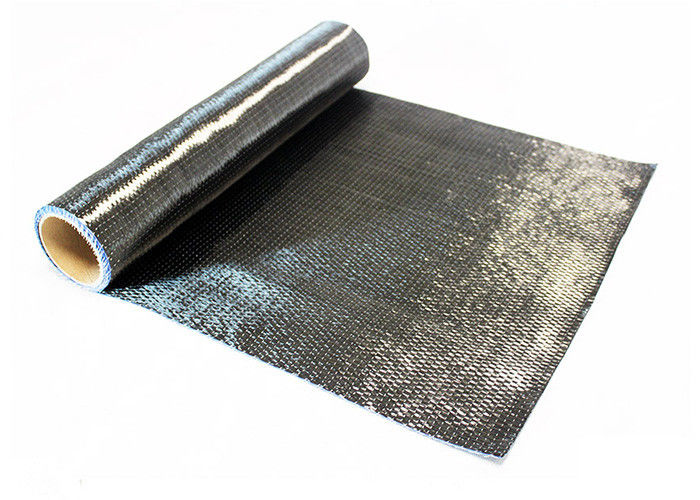

Easy Installation Fiber Reinforced Plastic Sheet , Carbon Fiber Roll No Maintenance Required

Fibre-reinforced plastic ( FRP; also called fibre-reinforced polymer, or in American English fiber) is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass (in fibreglass ), carbon (in carbon-fibre-reinforced polymer ), aramid, or basalt. Rarely, other fibres such as paper, wood, boron, or asbestos.

GRP Pipes Glass fiber reinforced plastics pipes, Sinopro Sourcing Industrial Products

.jpg)

FRP is also commonly referred to as fibreglass. It stands for fibreglass reinforced plastic (FRP). FRP consists firstly of fibres, namely glass fibres, and secondly of a plastic matrix surrounding the glass fibres. This matrix consists of either thermosets or thermoplastic material. Thanks to the combination of glass fibres and plastic matrix.

Properties of FiberReinforced Plastic (FRP)

.jpg)

Fiber-reinforced plastic (FRP) is also called fiber-reinforced polymer. It is a composite material made of a polymer matrix reinforced with fibers. The fibers are generally glass fibers, such as in fiberglass, carbon such as in carbon fiber reinforced polymer, aramid, or basalt. Sometimes other fibers are used like paper, wood, or, in the past.

FiberReinforced Concrete Advantages Types Properties Definecivil

Fiberglass, otherwise known as glass-reinforced plastic (GRP) or glass-fiber-reinforced plastic (GFRP), is a composite material made from extremely fine fibers of glass. These glass fibers are typically woven into a fabric-like mat or used as a reinforcement material in a plastic resin matrix.

Alternative Materials Fibrereinforced plastic RTF Rethinking The Future

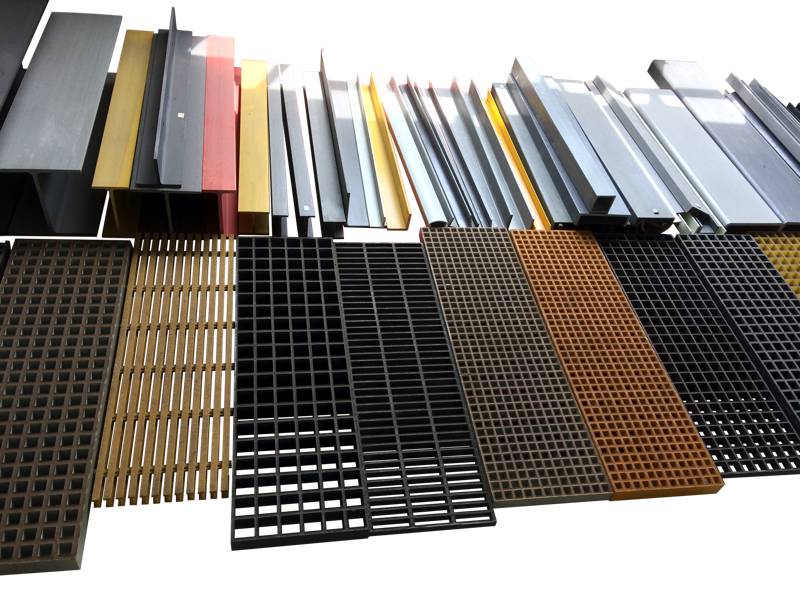

Fiber-reinforced plastic (FRP) composites have revolutionized the manufacturing sector. In many commercial, industrial, and municipal applications, FRP composites offer high-end performance at a fraction of the weight and cost of comparable metal materials. Construction, energy, aerospace, and other critical sectors are realizing the benefits.

Fiber Reinforced Polymers Concrete Repair and Restoration

Fiberglass Reinforced Plastic (FRP) Fiber Reinforced Plastic or Fiberglass Reinforced Plastic (FRP) products are created using high-quality polymer and fibers that enhance the surface's strength and durability. Since 1978, AMICO Seasafe® FRP products have been tested and proven in the harsh environment of the offshore Oil & Gas industry.

Carbon Fibers and CFRP SGL Carbon

Fiberglass (American English) or fibreglass (Commonwealth English) is a common type of fiber-reinforced plastic using glass fiber.The fibers may be randomly arranged, flattened into a sheet called a chopped strand mat, or woven into glass cloth.The plastic matrix may be a thermoset polymer matrix—most often based on thermosetting polymers such as epoxy, polyester resin, or vinyl ester resin.

Glass Fiber Reinforced Plastic (GFRP) Composites Market worth 45.12 Billion by 2019 Benzinga

Fiber reinforced plastic (FRP) is a type of plastic in which the strength of low strength plastic material is increased by means of high strength of fibers. Fiber reinforced plastics contains to main things one is matrix and another is fiber.

Fiberglass Reinforced Plastic CQ Fiberglass Direct

Fiber-reinforced composite material was found to be one of the most promising and effective types of composites, as it claims dominance over the majority of applications from topmost fields. There are numerous types of fibers available for fabrication of fiber-reinforced composites; those are categorized as natural and synthetic fibers.

Alternative Materials Fibrereinforced plastic RTF Rethinking The Future

The characteristics of fiber-reinforced plastics hinge upon factors such as the mechanical properties of the matrix and the fiber, the volumes of both and the length and orientation of the fibers in the matrix. FRPs have a low weight but are incredibly strong, and have good fatigue, impact and compression properties.

Fiber Reinforced Polymer Composites

Fibreglass wool, an excellent sound and thermal insulator, is commonly used in buildings, appliances, and plumbing. Glass filaments and yarns add strength and electrical resistivity to molded plastic products, such as pleasure boat hulls, automobile body parts, and housings for a variety of electronic consumer products. Glass fabrics are used.

Fibre Reinforced Plastic Products at Rs 300/kilogram FRP Products ID 11322931812

Carbon Fibre Reinforced Polymer (CFRP) Carbon fibers boast a high modulus of elasticity ranging from 200 to 800 GPa, with ultimate elongation between 0.3% and 2.5%. They do not absorb water, resist various chemical solutions, excel in fatigue resistance, and exhibit no corrosion or creep. Fig. 4: Carbon Fibre Reinforced Polymer Bars.

Fiber Reinforced Concrete Types, Advantages & Uses

The Fibre reinforced plastics (or fiber reinforced polymers) are a category of composite plastics that specifically use fibre materials (not mix with polymer) to mechanically enhance the strength and elasticity of plastics. The original plastic material without fibre reinforcement is known as the matrix. The matrix is a tough but relatively.

Glass Fibre Reinforced Plastic Sheets FERDOSIGROUP

Fiber-reinforced plastic is a composite material that combines a matrix (that's the plastic part) with a reinforcing fiber of some kind. The fibers embedded in the hardened plastic help it to hold together with much greater strength than the matrix alone would possess. Plastic is a synthetic form of polymer, which is a molecule that has a.

.